Traditionally paddles are made of Basswood because it is light weight. But the dense, open grained red oak was something different than the pine and basswood previously worked.

Students were given 5 feet of 6/4 red oak about 2"wide, and 52" of 4" wide 4/4 basswood to start with.

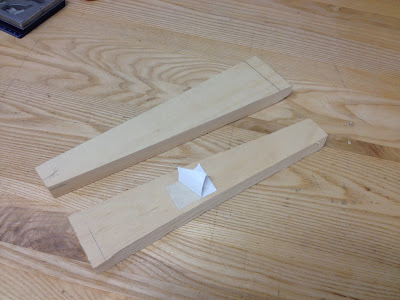

We then flattened or "Jointed" the edges of our 3 components to glue together

Once we were happy with out joints we glued them together. While the glue was drying it was time to work on templates.

I like the contrasting tones of the oak/basswood.

|

| Rosen and his laidout template |

Templates were made from cardboard, first Melanie makes a centre line to be symmetrical,

Rosen uses a compass to layout his template

|

| Using a compass for symmetrical radius's |

We choose the shape that felt represented us individually

Finally Andy cuts his with scissors and uses his sanding block and 80 grit sandpaper to perfect his shape.

Now it is time to flatten the bottom of the paddle the by planing the oak flush with basswood. The 6/4 oak is reduced to 1 1/4" along the neck too.

|

| Orlando then traces his template onto the basswood and oak. The centre line is used for reference.. |

|

| Relief cuts are ideal at this point |

|

| Then Andy rips off excess as best he can close to his layout lines. |

|

| Deann is not impressed with the time it takes to rip this one out with a Ryoba saw. |

|

| a work in progress |

Our well tuned hand planes do quick work on the surface of our paddles

Then a Rasp is in order to navigate curves

|

| Clamping it 'old school' |

The cheeks were added (1"X 1 1/2" X 6") before the evening was over so they could be worked the next day

Just like the bottom of the paddle, both edges to be glued together were flattened before lamination.

Tapering the paddle

Orlando has laid out his taper. 3/4 from the stem to 1/4 on the end

Rosen finds the center of his paddle and then lays out 2 lines on either side to target his taper

He then planes down to his lines

Calipers are used to determine the thickness away from layout lines

The Shaft

Our paddle Shaft is 1 1/2"wide and 1 1/8" thick

For example, this six inch ruler is placed with the 1" line on one side and the 5" line on the other side. That's 4" long on the diagonal. So half of 4" is 2". Count 2" from either of the edges and find the center of the blank at the 3 inch mark.

Now that we have the center point, we have marked out 3/4" from either side to mark out the 1 1/2" wide shaft on center.

The same was done on the edge of the shaft to layout the 1 1/8" thickness. From our center we marked 9/16" either side to total 1 1/8"

Time to plane down to our targets.

Andy asked about the layout for his handle. I gave him my 2 cents and came back later with a toonie.

The Handle should span about 3 1/2"

We do our best to stay within our layout lines.